System Overview

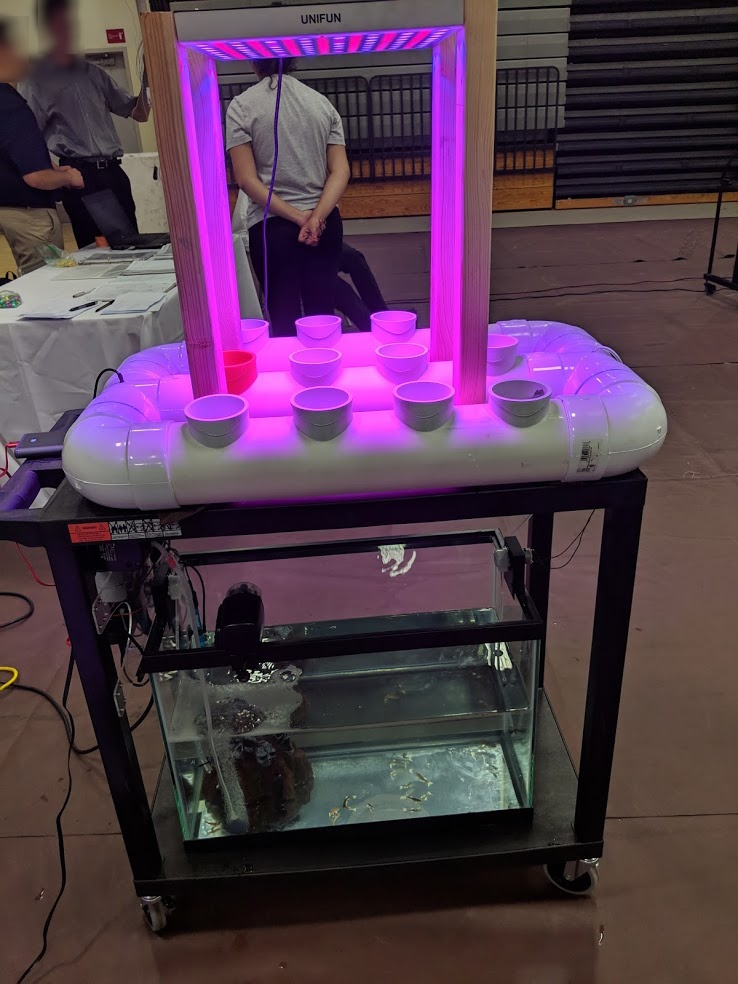

Aquaponics is a farming technique which combines both aquaculture and hydroponics subsystems into a single cooperative environment. Our system utilizes a fully autonomous aquaponics systems which records temperature and pH readings from the system for use in research and practical demonstrations. Water is cycled throughout the auqaponics from the aquaculture tank into the hydroponic tubes, which help to filter the water, which is then pumped back into the tank at the bottom. This process repeats cylically allowing for a symbiotic relationship between the fish in the tank and the plants being grown above them.

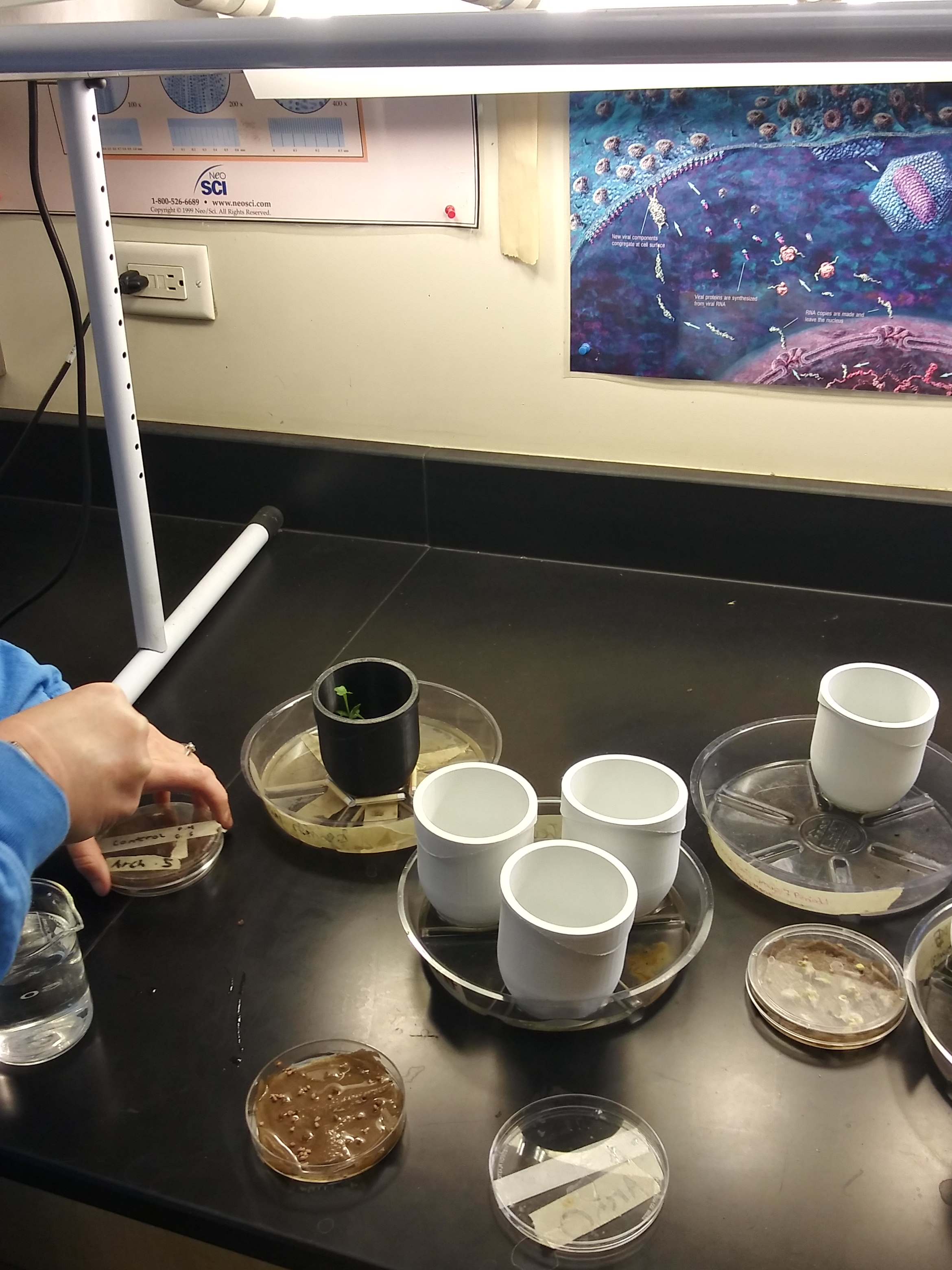

For this project, minnows were chosen to be used in the aquaculture portion of the system. The minnows were fed daily by an off-the-shelf automatic fish-feeder, eliminating the need for manual human feeding.

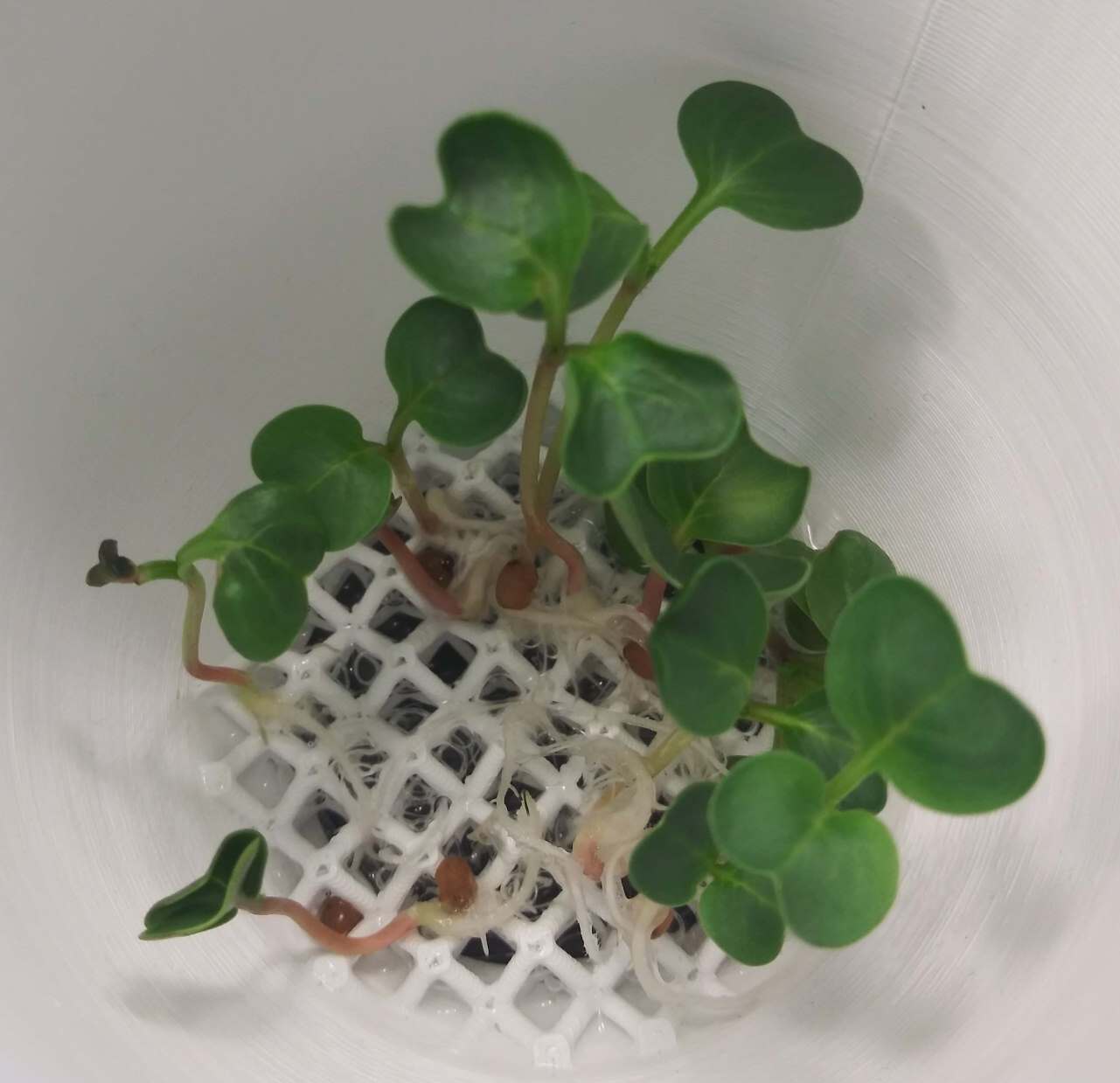

In the upper, hydroponic section of the system, plants are grown in three enclosed channels, each with four openings filled by one of the NFT Units. The NFT Units contain the plants (in this case, raddish sprouts were grown) and allow for passive watering of the plants as water flows through the channels. Above the channels, a combination UV/IR/Red/Blue growlight is held to act as an artificial light source.

The units for holding the plants were developed based around the Nutrient Film Technique (NFT). This allows for very efficient, purely hydroponic feeding of the plants through their roots. The roots grow through the lattice structure in each cell and secure themselves to the base as they leach nutrients from the water while still mostly exposed to the surrounding air.

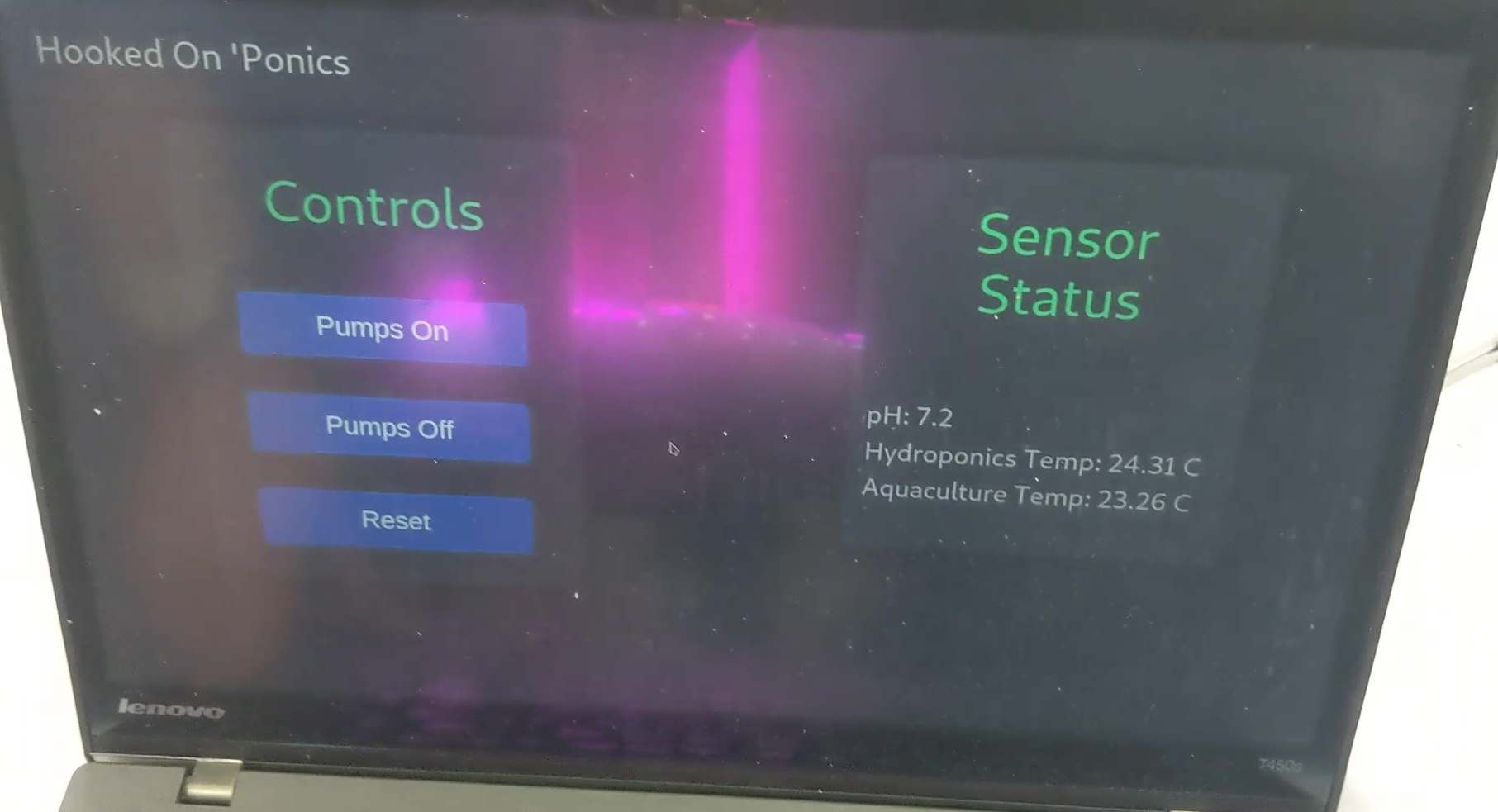

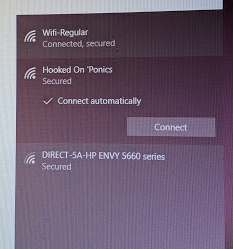

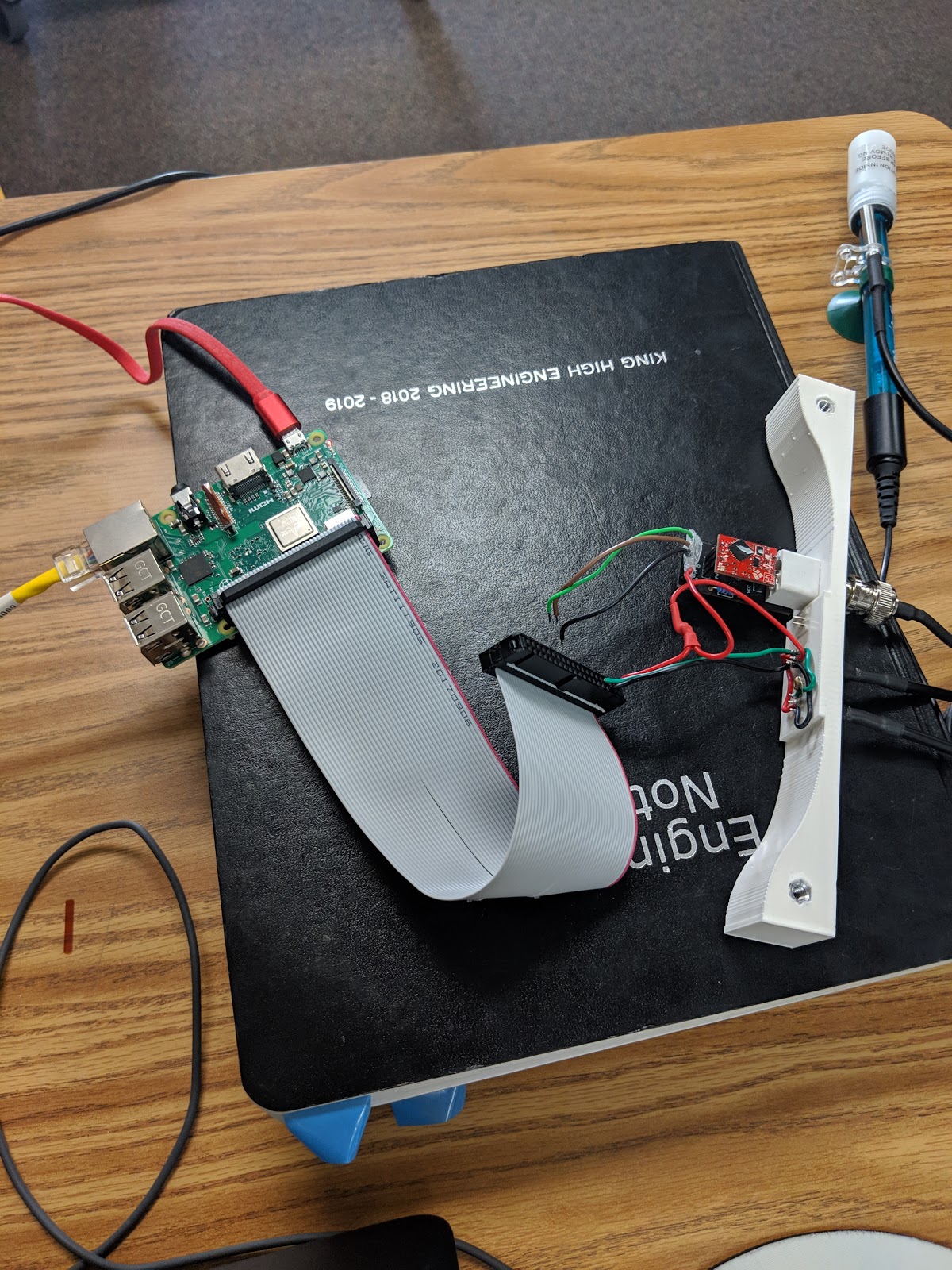

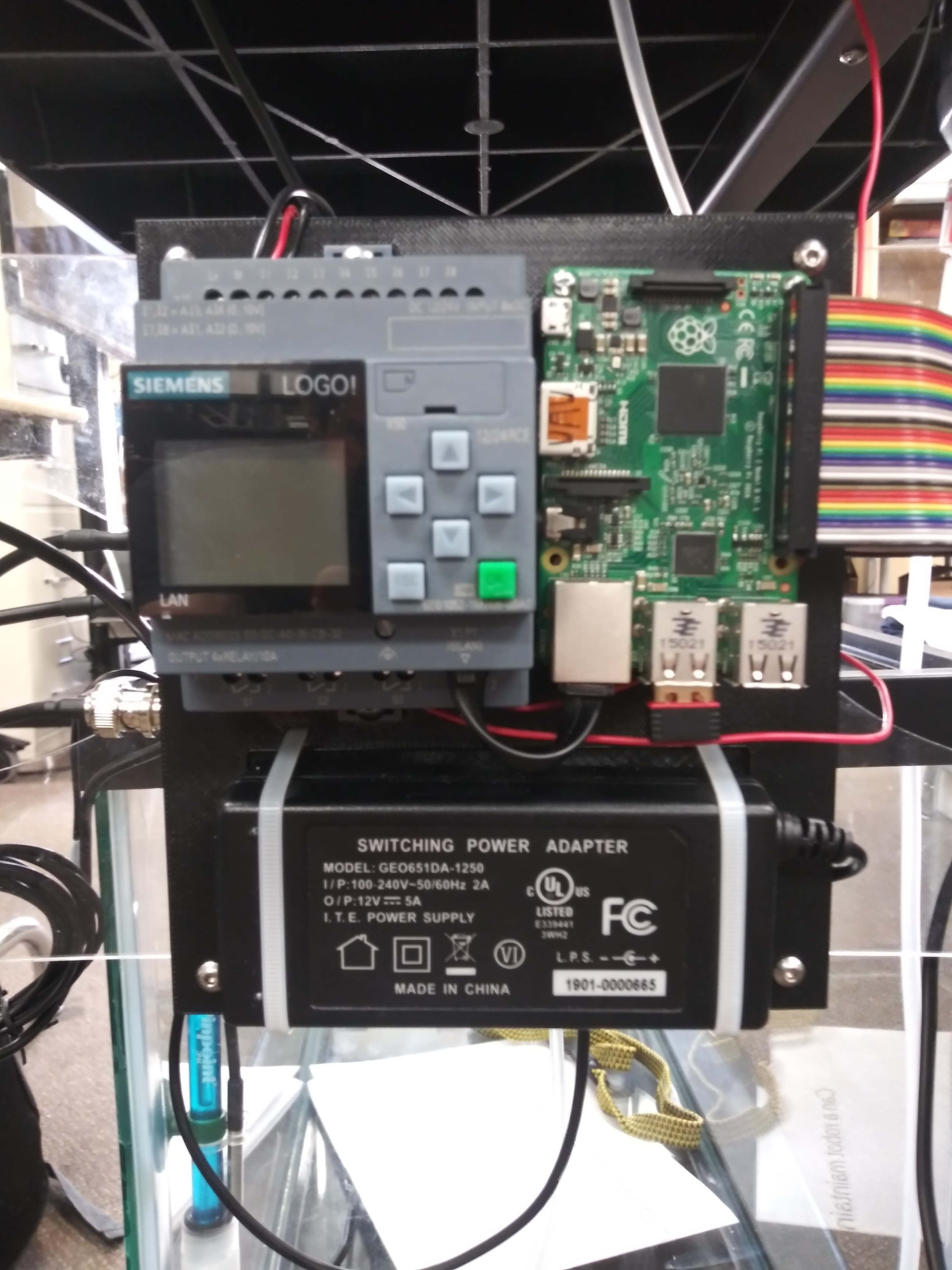

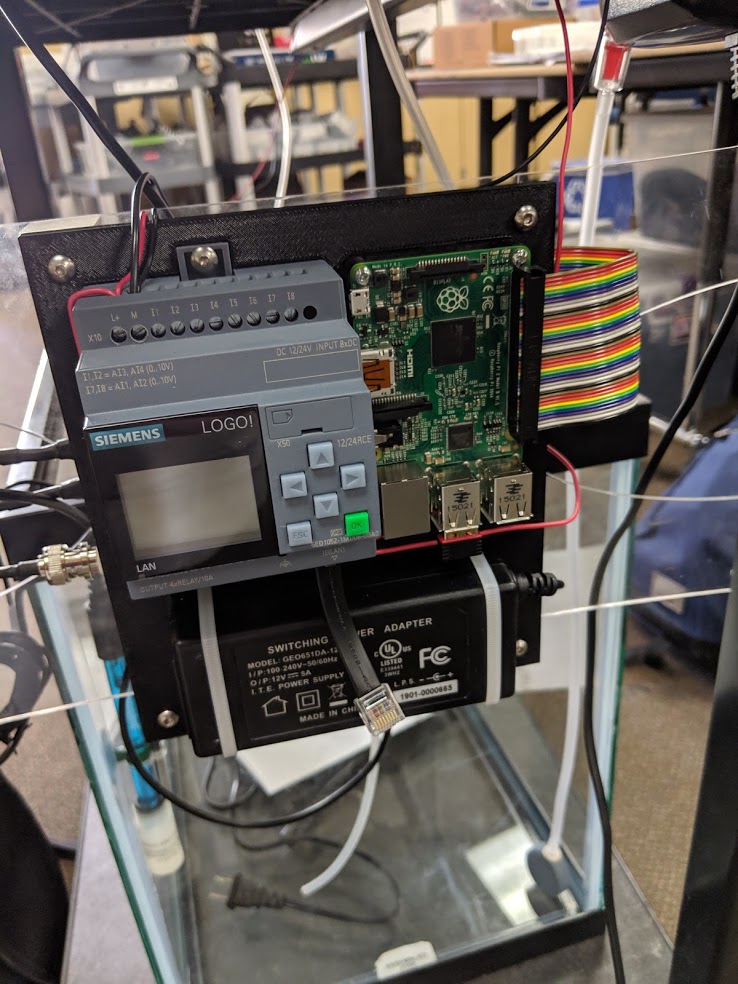

The whole system was controlled by the combined use of a Programmable Logic Controller (PLC) and a Raspberry Pi. The PLC was used to control essential tasks that needed to be more rugged and run without interruption for long periods of time, without worrying about software updates or data transfers. The Raspberry Pi was used to control all forms of data collection and analysis from the temperature sensors and the pH sensors. This system was built in a modular fashion to allow the addition of more complex sensors in future research.